Homeowners of a new build house or apartment don’t expect to purchase a property with a 'bouncy' floor - or worse still, tile failures due to deflection.

Knauf Dry screed panels are the solution. Precision engineered and made from the highest quality gypsum fibreboard, Knauf GIFA FHB Boards create strong, monolithic floor structures ensuring stability and strength for almost any type of floor finish.

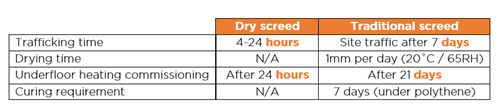

Time is often of the essence and dry screed floor panels are the solution. Whether building on site or in an off-site factory the boards are quick and easy to install. The interlocking panels and the installation system require just 24 hours before being fully trafficable. This allows floor finishes to be installed much sooner than with traditional screed.

As the dry screed panels are secured using glue and/or screws there is no requirement for water to lay the panels. This saves approximately 11ltrs of water for every 1m2 when compared to 75mm of traditional screed, (based on water costs of £119 per 1000ltrs) saving £1,309 for a 1000m2 project. On top of this, dry screed boards eliminate the need for daily wash out of the pumping equipment and disposal, saving both the water usage associated with this and the challenge of disposing of the wastewater.

Due to the high density of the dry screed boards, they provide the support needed without adding significant height to the floor. In commercial uses an 18mm board will often be sufficient, and so significantly less than the 75mm needed with the traditional method. This gives up to 57mm extra floor to ceiling height in each room.

The high-density boards are particularly effective at minimising noise, but when backed with wood-fibre, they provide further enhanced acoustic performance and excellent impact in sound reduction. Fabulous news for projects such as multi-occupancy residential, hotels, hospitals, and schools.

* Independently verified by the Building Services Research and Information Association (BSRIA)

All great news for installers and end users alike!

When used with under floor heating, the system will reduce CO2 emissions due to its increased thermal efficiency when compared with chipboard and improve under floor heating response times compared with traditional screed. It will also optimise the benefit of air and ground source heat pumps. So whether it’s during the build phase or when the building is occupied, Knauf dry screed boards are helping to reduce the environmental impact of the building.

Dry screed flooring panels/boards are precision engineered from the highest-quality gypsum fibreboard to create strong monolithic floor structures. The slim, dense boards have a solid floor feel when installed. System solutions are available whether you are adding screed to a solid substrate or need a spanning solution over joists, pedestals or on a cradle and baton system. Learn more here.

The Knauf range of dry screed flooring is available through Encon’s national branch network. The boards are suitable for use on solid substrates, over cradle and baton systems, direct onto joists or with pedestals. Contact us to find out more.